Are you a tool manufacturer looking to transition from PVD outsourcing to In-House PVD but don’t know where to get started?

Meet Bob

Bob is the owner of a cutting tool manufacturer.

He has relied on a third-party PVD coating supplier to coat his products for the past ten years. Everything was great until the recent year as Bob began to scale his business and introduce new products that also require PVD coating.

On the one hand, Bob is experiencing a slower turnaround time, an increase in defective parts, and cost increase from the PVD coating supplier; on the other hand, Bob’s customers are demanding a faster turnaround time, better quality, and cost reduction. Bob has two options: (a) look for an alternative supplier is located a few hundred miles away, or (b) set up his PVD coating department as he has enough volume and resources to allocate.

The only question is he doesn’t know where to get started as he has been outsourcing PVD coating for the last decade.

If this sounds familiar, download this Free PVD Coating System: A Buyer’s Guide today.

In this Free PVD Coating System Buyer’s guide, we will provide you with a roadmap to help you navigate through the entire PVD coating system selection and buying process based on our 27 years of experience in the PVD Coating industry

You Will Learn

What is PVD Coating and Most Common PVD Coating Types

How to evaluate the pros and cons of PVD outsourcing vs. In-House PVD

What are the Key Challenges with PVD Outsourcing

How to assess your current business needs and decide if PVD In-House is the right decision for you

How to conduct a cost analysis of PVD outsourcing VS PVD In-House

How to ask the right questions to PVD Coating System manufacturers before you make a buying decision?

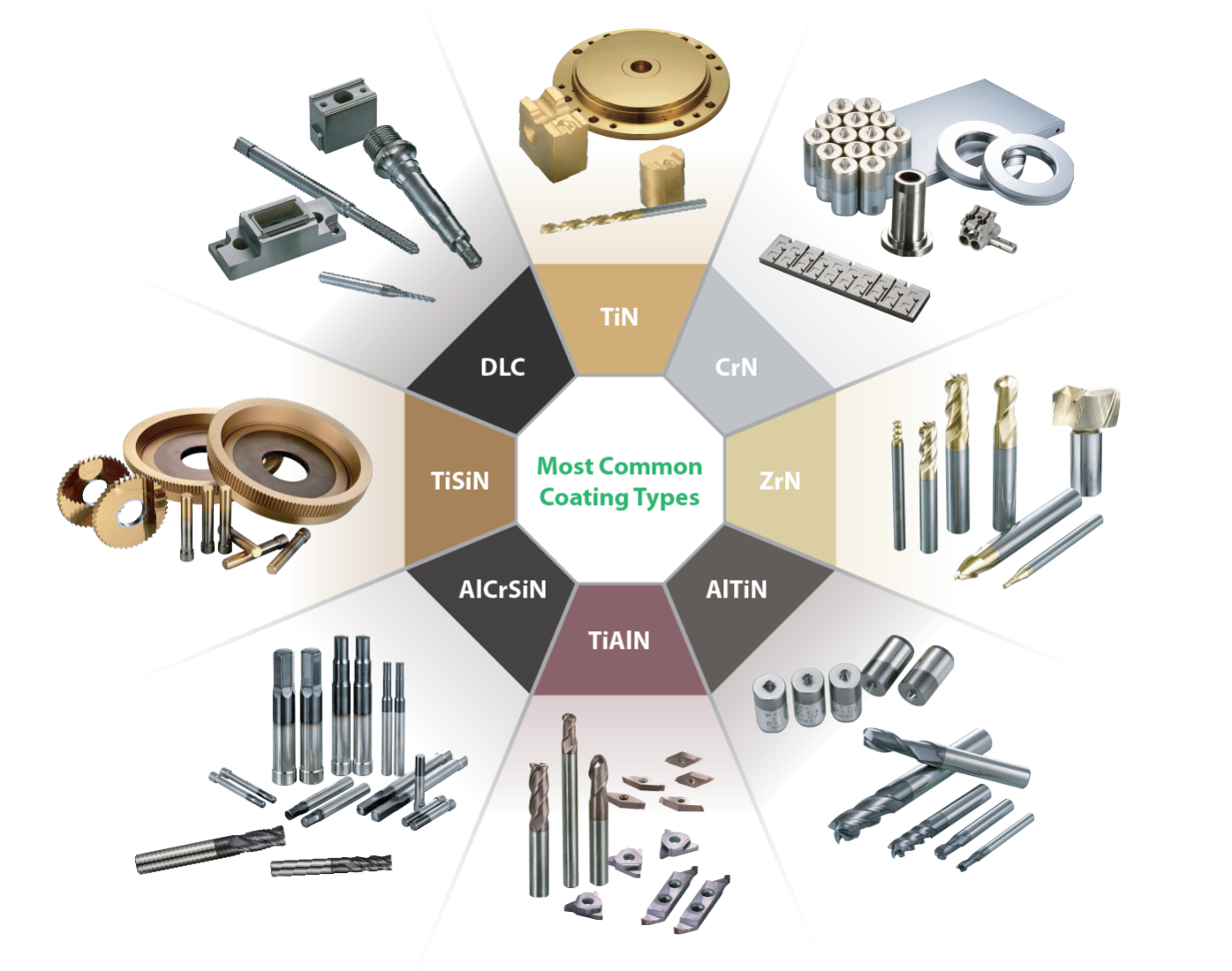

What is PVD Coating and Most Common PVD Coating Types

Physical Vapor Deposition (PVD) is the vacuum-coating technique used to enhance the properties and performance of metal, ceramic, or plastic objects by depositing thin metallic or ceramic film coatings on their surface.

The most common PVD coating processes used today are cathodic arc evaporation and magnetron sputtering. These coating processes occur in a vacuum deposition chamber where reactive gases such as nitrogen, acetylene, or oxygen are introduced to create various compound coatings.

The most common coating types are TiN, CrN, ZrN, AlTiN, TiAlN, AlCrSiN, TiSiN, and DLC. We will review the benefits, physical properties, and applications of each coating type. Bob has been relying on the PVD coating supplier; now, he can explore other coating possibilities to apply to his products.

How to evaluate the pros and cons of PVD outsourcing vs. In-House PVD

Products manufactured up to the pre-coating stage are then sent to either (a) the in-house PVD coating department or (b) a third-party PVD coating provider. If you are looking to transition from PVD outsourcing to In-House, you must understand the Pros & Cons of the two options.

PVD Outsourcing: Third-party PVD coating suppliers are equipped with a PVD coating system and offer various coating options. These suppliers may coat your products with other customers’ products in the same batch. Expect a time delay from the time pre-coated products are sent to the time coated products are received. This is an excellent option for manufacturers with small quantities or low frequency.

PVD In-House: Manufacturers integrate the PVD coating system as part of the production line and require purchasing capital equipment. PVD in-house is an excellent option for manufacturers that regularly coat large quantities and are concerned with third-party PVD coating suppliers’ quality and delivery time.

What are the Key Challenges with PVD Outsourcing

Increase in Customer Demand

Customers are demanding faster turnaround times, different types of coatings, and a cost reduction.

Increase in Time and Cost to Prepare/Inspect Products

It takes time to prepare, send, wait, receive, and inspect products to the service provider.

Increase in Unit/Batch Cost

The average cost per unit increases over time, but passing this increase to customers doesn’t seem right.

Increase in Business Development

As the business grows, some service providers cannot keep up as they have other customers to serve.

Customized Coating

Differentiating from the crowd matters. An exclusive coating would help, but you don’t know how to make these happen.

How to assess your current business needs and decide if PVD In-House is the right decision for you

Are you spending more than USD 100K annually on PVD outsourcing?

Bob’s cutting tool company is spending more than USD 100K annually on PVD outsourcing with an annual volume between 20,000-30,000 units. Investing in a PVD coating system will significantly reduce Bob’s cost per part and increase his overall bottom line.

Is your PVD coating service turnaround longer than 24 hours?

As Bob’s business continues to expand, his customers are demanding a faster turnaround. Bob’s PVD coating supplier has a hard time keeping up with the delivery schedule as they have other customers to serve at the same time. The advantage of owning an in-house PVD coating department allows Bob to take full control over the production schedule - even if it means Bob has to run an extra shift or two to get the job done.

Have you ever received defective or damaged tools from the PVD coating supplier?

If you are experiencing QA issues, be it from the PVD coating suppliers or shipping company, this could affect your bottom line and customer satisfaction. When you own your in-house PVD coating department, the system is integrated as part of the production, and any defects can be identified and rectified on the spot.

How to conduct a cost analysis of PVD outsourcing

For a tool manufacturer, everything (almost) is about dollars-and-cents.

On average, PVD outsourcing cost per part is around USD 5.00 for a regular ⌀ ½” end mill with AlTiN coating, which does not include additional fees such as pack/unpack cost, shipping cost, and QC cost that some of the manufacturers tend to neglect.

Formula to calculate your PVD outsourcing cost:

A. What is your annual capacity (units)?

B. Cost to Pack/Unpack for Coating per unit.

C. Cost to Ship To/From Supplier per unit

D. Cost to inspect coated per unit?

E. Coating cost per unit?

Outsourcing Cost Calculation: [A] x [B+C+D+E]

Once you have completed the calculation, you might be surprised by how much you spend on PVD outsourcing.

How to ask the right questions to PVD Coating System manufacturers before you make a buying decision?

When was the last time you purchased a car? How did you end up buying the vehicle you're currently driving? There is a vast amount of information available when purchasing a car, but not when you want to buy a PVD Coating System. You can’t go to your next-door neighbor or call your friends to get an opinion on PVD Coating Systems. Most of the information is only available on PVD Coating System manufacturer’s websites, and you can only access more information by contacting the manufacturers.

Unless you have a specific brand and model in mind, you will most likely need to conduct extensive research, negotiation, and coating testing before you sign on the dotted line. So before you pick up the phone or send an email, we have compiled some of the commonly asked questions to help you navigate through this process.

What’s included in the FREE PVD Coating System: A Buyer’s Guide