Applications

Applying a PVD coating makes tools more resilient and stronger. This increased resilient increases tool lifespan while the increased strength improves cutting performance.

One of the most common uses of PVD coating is on cutting tools. The objects’ increased strength and resilience can save your company a lot of money as it improves the objects in many ways:

Enhanced Performance

Cutting tools with PVD coating can cut much harder materials. This is especially useful for applications that require a very tough edge, such as threading, end-milling, grooving, and drilling.

Increased Speed

The tools can be run faster, which decreases cycle time and allows components to be produced more quickly.

Longer Lasting

The increased resilience provided by the coating means the tools don’t flake or wear-out as much. This greatly increases the tools’ surface life and they don’t need to be replaced as frequently. They also avoid the built-up edge that often develops.

Temperature Resistance

The tools can be operated at a higher temperature with no harm, which facilitates particular uses.

Less Costly Fluids

Cutting tools with PVD coating need less cutting fluid (which can cost as much as 15% of total production costs) because PVD coatings such as TiAlN can deal with very high temperatures without requiring any additional liquid.

One of the most common uses of PVD coating is on cutting tools. The objects’ increased strength and resilience can save your company a lot of money as it improves the objects in many ways:

Enhanced Performance

Cutting tools with PVD coating can cut much harder materials. This is especially useful for applications that require a very tough edge, such as threading, end-milling, grooving, and drilling.

Increased Speed

The tools can be run faster, which decreases cycle time and allows components to be produced more quickly.

Longer Lasting

The increased resilience provided by the coating means the tools don’t flake or wear-out as much. This greatly increases the tools’ surface life and they don’t need to be replaced as frequently. They also avoid the built-up edge that often develops.

Temperature Resistance

The tools can be operated at a higher temperature with no harm, which facilitates particular uses.

Less Costly Fluids

Cutting tools with PVD coating need less cutting fluid (which can cost as much as 15% of total production costs) because PVD coatings such as TiAlN can deal with very high temperatures without requiring any additional liquid.

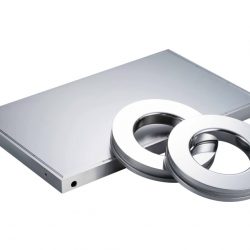

A PVD coating can also reduce wear on forming and punching dies and the lower friction of the tools means less money spent on expensive lubricants.

PVD coating also provides numerous benefits for forming and punching tools. The objects’ enhanced hardness and low friction increases their effectiveness in many ways. PVD coating in forming and punching dies will:

Increase Wear Resistance

The high hardness reduces wear on forming and punching dies, which increases their working lifespan and their general effectiveness. Abrasive wear is decreased as well, resulting in less scratching and more resistance to continual use. Also, they avoid any built-up edges that can otherwise develop.

Reduce Sticking

With the right coating, material sticks a lot less to the forming and punching tools, resulting in quick release of components without influencing their working lifespan. This forms and punches a better final product, and makes it much easier to clean the tools.

Reduce the Need for Lubricants

The increased ease of use with PVD coated forming and punching tools means that there is much less need for expensive lubricants.

PVD coating also provides numerous benefits for forming and punching tools. The objects’ enhanced hardness and low friction increases their effectiveness in many ways. PVD coating in forming and punching dies will:

Increase Wear Resistance

The high hardness reduces wear on forming and punching dies, which increases their working lifespan and their general effectiveness. Abrasive wear is decreased as well, resulting in less scratching and more resistance to continual use. Also, they avoid any built-up edges that can otherwise develop.

Reduce Sticking

With the right coating, material sticks a lot less to the forming and punching tools, resulting in quick release of components without influencing their working lifespan. This forms and punches a better final product, and makes it much easier to clean the tools.

Reduce the Need for Lubricants

The increased ease of use with PVD coated forming and punching tools means that there is much less need for expensive lubricants.

Coating a mold or die with PVD increases filling while decreases the chance of the final product being distorted. The molds also last longer and are easier to clean.

Moulding and die casting can be very difficult. However, a PVD coating can provide numerous benefits that simplify the process and greatly lower manufacturing costs:

Increased Speed

You can run the tools faster, which shortens cycle times so that components can be produced more quickly. As the coating decreases the objects’ stickiness, the melt inside flows faster and more easily fills the mould.

Improved Final Product

This lack of sticking also makes it easier to release the mould. This decreases the chance that the final product will be distorted, while also improving the final surface finish and increasing the product’s resilience so that it will last longer.

Longer Lasting

The coating also greatly increases the moulds’ service life so that they don’t need to be replaced as frequently. The moving parts are also protected against scuffing.

Easy to Clean

As there are fewer deposits at the end of the process, the moulds are much easier to clean.

No Expensive Lubricants

The increased ease of flow means expensive lubricants aren’t required.

Moulding and die casting can be very difficult. However, a PVD coating can provide numerous benefits that simplify the process and greatly lower manufacturing costs:

Increased Speed

You can run the tools faster, which shortens cycle times so that components can be produced more quickly. As the coating decreases the objects’ stickiness, the melt inside flows faster and more easily fills the mould.

Improved Final Product

This lack of sticking also makes it easier to release the mould. This decreases the chance that the final product will be distorted, while also improving the final surface finish and increasing the product’s resilience so that it will last longer.

Longer Lasting

The coating also greatly increases the moulds’ service life so that they don’t need to be replaced as frequently. The moving parts are also protected against scuffing.

Easy to Clean

As there are fewer deposits at the end of the process, the moulds are much easier to clean.

No Expensive Lubricants

The increased ease of flow means expensive lubricants aren’t required.

PVD coating is useful for a wide variety of specialized industries, including automotive, aerospace, medical, energy, food processing and packaging, recreational equipment, electronics & semiconductors, and decorative coating.

Automotive

PVD coating is commonly used on automotive components, especially the combustion engine, which is run at a high temperature with a high-wearing piston ring moving back and forth. A PVD coating, especially DLC, greatly decreases friction and can also enhance the combustion efficiency in the engine’s chamber, increase wear resistance, reduce energy loss caused by friction, improve fuel efficiency, and reduce GHG (greenhouse gas) emissions. This makes the engine far more efficient. In addition, coating can provide a perfect metallic look for plastic components.

Recreational Equipment

PVD coatings that enhance hardness, lower friction, and create a shining metallic appearance can be very useful to manufacturers of recreational equipment, such as sports products and bicycles. The coating can enhance resistance to wear, increasing the hitting distance of golf clubs and other equipment, reducing the need for lubricants in the driving gear of bicycles (so that your pants do not become contaminated by lubricant), and generally increase equipment performance. Furthermore, the shining metallic look available in different colors can help you to customize your equipment with the appearance you want.

Electronics & Semiconductors

PVD coating is used in both the electronics and semiconductor industries. PCB (printed circuit board) routing requires precise cutting using a needle-sized end mill. Without applying a hard PVD coating to increase routing performance and lifespan, the mill would be very weak and easily worn, decreasing the cutting performance. Furthermore, PVD coating can protect electronic products from chemical erosion. Products such as IC packaging molds require high precision after many runs of production and a PVD coating layer decreases the molds’ adhesive effect so that they work longer and release more easily. All of this saves manufacturers a ton of money.

Medical Implements

PVD coating also plays an important role in medical implements. The implements require instant and smooth release after cutting the cutter and tissue (skin and flesh). Poor cutting would result in bad wound recovery, increasing patient time in the hospital and reducing patient turnaround. Not only do PVD coatings of medical implements decrease sticking, they also reduce corrosion inside the patients and provide a bio-compatible surface, which lets the implants work more effectively and last longer.

Aerospace Blades

The blades on helicopters and the turbine blades on airplanes face such difficulties as sand corrosion over deserts and acid particles erosion in the atmosphere. PVD coating has been adopted by helicopters, commercial airplanes, and other aircrafts as the solution to these problems. Not only does PVD coating reduce the corrosive and erosive wear of the blades, but it also enhances high temperature resistance, reduces the need for lubricants, and increases the lifespans of the blades up to 20 times, depending on the working condition.

Decorative Coating

PVD’s high quality coating can be used to enhance the decorative appeal of many high-end products, such as jewellery, handles for doors and furniture, and a wide variety of tools. Numerous resilient colour coatings are available, which can provide vivid shine and enhanced colour to such materials as brass, nickel, steel, and gold. Furthermore, coating can provide a compelling metallic appearance to all kinds of non-metallic objects. And the enhanced resilience that PVD coatings deliver means that the objects become highly scratch-resistant, so that even objects that receive a lot of use, such as jewellery, remain attractive and smooth.

Automotive

PVD coating is commonly used on automotive components, especially the combustion engine, which is run at a high temperature with a high-wearing piston ring moving back and forth. A PVD coating, especially DLC, greatly decreases friction and can also enhance the combustion efficiency in the engine’s chamber, increase wear resistance, reduce energy loss caused by friction, improve fuel efficiency, and reduce GHG (greenhouse gas) emissions. This makes the engine far more efficient. In addition, coating can provide a perfect metallic look for plastic components.

Recreational Equipment

PVD coatings that enhance hardness, lower friction, and create a shining metallic appearance can be very useful to manufacturers of recreational equipment, such as sports products and bicycles. The coating can enhance resistance to wear, increasing the hitting distance of golf clubs and other equipment, reducing the need for lubricants in the driving gear of bicycles (so that your pants do not become contaminated by lubricant), and generally increase equipment performance. Furthermore, the shining metallic look available in different colors can help you to customize your equipment with the appearance you want.

Electronics & Semiconductors

PVD coating is used in both the electronics and semiconductor industries. PCB (printed circuit board) routing requires precise cutting using a needle-sized end mill. Without applying a hard PVD coating to increase routing performance and lifespan, the mill would be very weak and easily worn, decreasing the cutting performance. Furthermore, PVD coating can protect electronic products from chemical erosion. Products such as IC packaging molds require high precision after many runs of production and a PVD coating layer decreases the molds’ adhesive effect so that they work longer and release more easily. All of this saves manufacturers a ton of money.

Medical Implements

PVD coating also plays an important role in medical implements. The implements require instant and smooth release after cutting the cutter and tissue (skin and flesh). Poor cutting would result in bad wound recovery, increasing patient time in the hospital and reducing patient turnaround. Not only do PVD coatings of medical implements decrease sticking, they also reduce corrosion inside the patients and provide a bio-compatible surface, which lets the implants work more effectively and last longer.

Aerospace Blades

The blades on helicopters and the turbine blades on airplanes face such difficulties as sand corrosion over deserts and acid particles erosion in the atmosphere. PVD coating has been adopted by helicopters, commercial airplanes, and other aircrafts as the solution to these problems. Not only does PVD coating reduce the corrosive and erosive wear of the blades, but it also enhances high temperature resistance, reduces the need for lubricants, and increases the lifespans of the blades up to 20 times, depending on the working condition.

Decorative Coating

PVD’s high quality coating can be used to enhance the decorative appeal of many high-end products, such as jewellery, handles for doors and furniture, and a wide variety of tools. Numerous resilient colour coatings are available, which can provide vivid shine and enhanced colour to such materials as brass, nickel, steel, and gold. Furthermore, coating can provide a compelling metallic appearance to all kinds of non-metallic objects. And the enhanced resilience that PVD coatings deliver means that the objects become highly scratch-resistant, so that even objects that receive a lot of use, such as jewellery, remain attractive and smooth.