Additional Services

In addition to our PVD coating equipment and coating services, we provide the following services:

Research & Development

Our experts at the Surface Engineering Research Center continuously work to improve coating systems and processes for industrial applications. This includes developments in the areas of:

- Surface Engineering

- Plasma Analysis

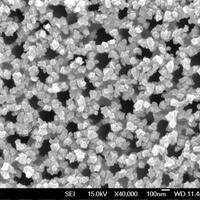

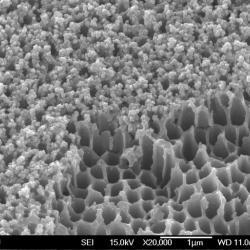

- Nanocomposite and Multilayered Coating Technologies

- System and Process Integration by Cathodic Arc Evaporation and Unbalanced Magnetron Sputtering

Turnkey Solutions and Accessory Supplies

If needed, we can provide a turnkey system developed to make your equipment easy to use so you can start coating immediately. This system includes:

- Pre-Coating Surface Treatment

- Eco-Friendly Cleaning Line

- Post-Coating Surface Finishing Equipment.

- State-Of-The-Art QC Laboratory